Electromechanical Stretcher

PATENT PENDING

e:stretch

The future of stretchers is now

Leveraging our years of expertise, we’ve engineered an extraordinary masterpiece: e:stretch.

Uniquely designed with significantly fewer parts, it reduces wear and tear, enhances safety, and simplifies cleaning. Experience increased efficiency, lower costs, and a more sustainable operation. The absence of a bulky tank creates a clutter-free workspace.

e:stretch

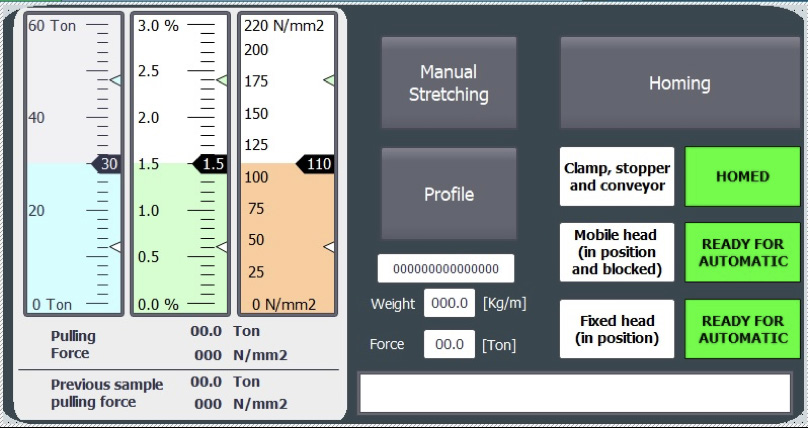

Profile resisting force instant reading

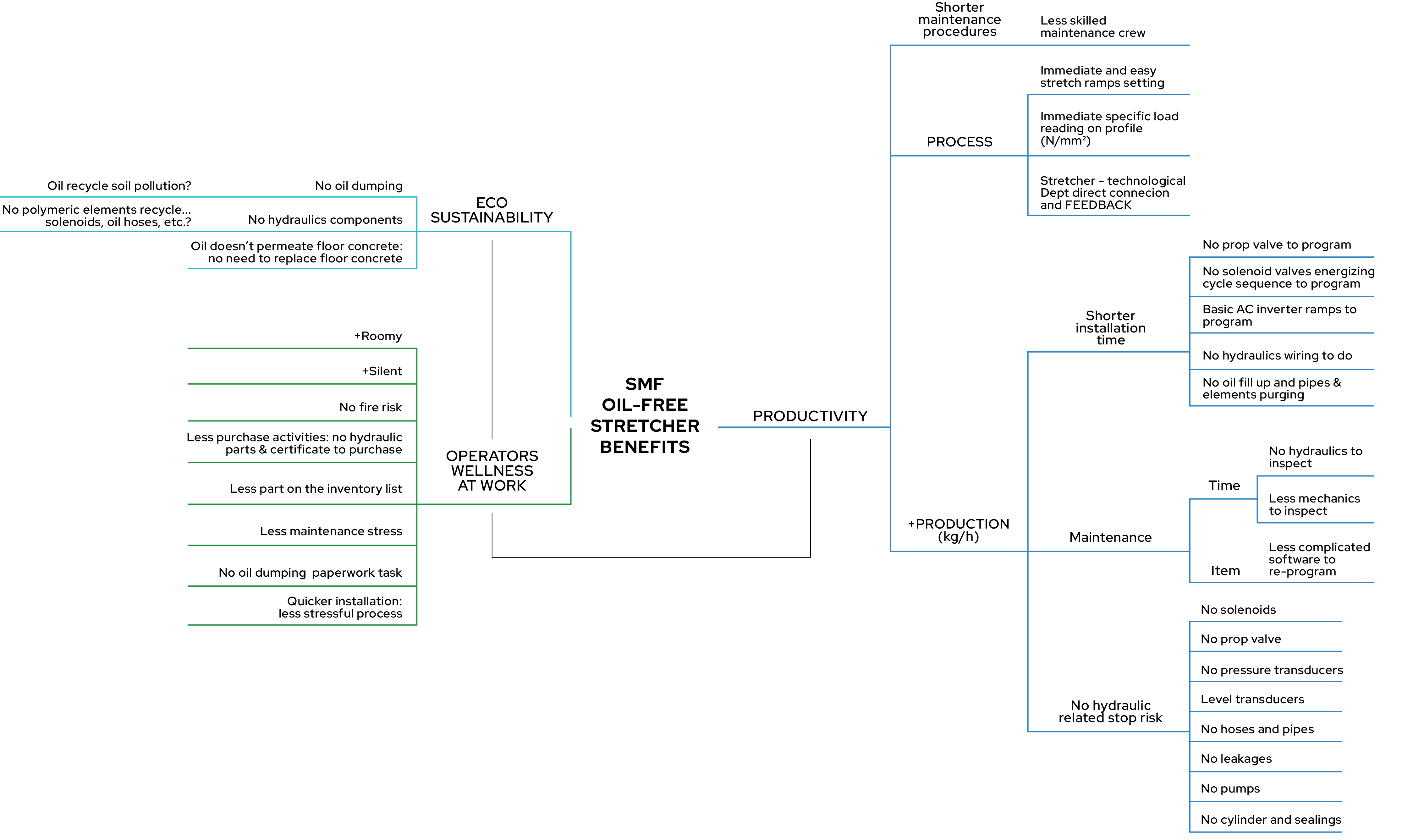

The following can be in real time selected:

- The yield strength of a chosen alloy

- The relationship between the yield strength and elongation of profiles

- The tonnes of force application

- The acceptable resistant yield strength limit of a profile and the consequent alarm if this is not reached: if an elongation with an ‘X’ resistant force is detected when the force should have been higher, this means that the profile tends to resist less and the profile yield strength is lower than expected. In this case, the system generates an alarm or pop-up message informing of the anomaly. Alternatively, this anomaly can be immediately sent to the ERP where it is analysed and, if necessary, a signal sent to production to stop because there are problems with the alloy itself or with the treatments upstream of the stretching process. The stretcher becomes a ‘process filter’ that did not exist before.

The role of the operator is eliminated: it is no longer necessary to touch the profile with the hand to check its stretchability.

e:stretch

Innovative and sustainable

- Oil Spill: Oil leaks onto the floor can contaminate soil and water sources, posing a threat to ecosystems.

- Minimizes Waste: By eliminating the need for oil, there is less waste to manage at the end of the machine’s life, reducing the environmental impact associated with oil disposal and recycling.

- Lower Polymer Use: Electric machines typically require fewer components made from polymers, such as valves, gaskets, and seals, which are produced through energy-intensive processes. This reduction lowers the demand for petroleum-based products, decreasing overall plastic waste.

- Energy Efficiency: Electric systems are often more energy-efficient than those powered by fossil fuels, leading to reduced overall energy consumption and a smaller carbon footprint. Overall, an oil-free electric machine enhances environmental sustainability by reducing pollution, waste, and resource consumption.

e:stretch

Improved security

Safety remains a top priority in any industrial setting, and the redesign of machines from hydraulic to electric has introduced numerous enhancements. Electric systems typically feature advanced control mechanisms that offer precise performance and predictive maintenance capabilities. This means that potential issues can be proactively detected and addressed, reducing the risk of accidents. Additionally, electric machines generally operate at lower noise levels and produce fewer vibrations, contributing to a safer working environment by minimizing hazards associated with traditional hydraulic systems.

The redesign of these machines has led to significant improvements in operational processes. Electric machinery often responds more quickly and reliably than hydraulic counterparts, resulting in faster production times and increased productivity. The interoperability of electric systems allows for seamless integration with modern automation technologies, enabling companies to employ smarter, more efficient workflows. This adaptability not only enhances overall performance but also paves the way for innovation in manufacturing techniques.

e:stretch

Stretcher Benefits